FireShell Quality

Fine Wine and Fine Fabric

FireShell is a unique textile blend manufactured in the UK

Producing high quality fabrics is like producing high quality wine. Blended wines are the result of winemaking magic. Vintners combine different grapes to create something original and new. Every bottle is the result of a meticulous testing and tasting process.

Creating our high-quality fabric has followed a similar process by combining the qualities and capabilities of a range of textiles to create the PARATEC FIRESHELL EXTREME fabric, a UK manufactured, unique textile blend. The experience, knowledge and credibility of Dale Intertec has been acquired over many years of providing high quality/military grade fabrics and textiles to a wide range of emergency agencies. We bring experience, understanding, and capability to the development and manufacture of our products.

Basing manufacturing in the UK ensures we can maintain the quality and consistency required of a potentially lifesaving piece of technology – we also have more control over supply chains.

Design Criteria for a Lithium Battery Fire Retardant Textile

The fire industry already has some excellent fabrics and standards for fire resistant textiles and fabrics, and we have adopted/adapted these standards to our fire blankets. This approach helps our customers understand the performance criteria and capability of the products and allows performance benchmarking between various fabrics on the market to compare cost v benefits, and secure value for money.

FireShell - Fire Retardent Quality Guaranteed

Our approach has two major attributes – the quality of our material and the fact that the textiles used have been specifically selected and tested to make sure they can solve a specific set of fire related problems. The challenge is that the material of the textile must be able to withstand heat and fire intensity of new energy technologies such as lithium batteries.

Heat Resistance

The key attribute is an ability to withstand the heat and fire load generated by a car fire (including electric vehicles). The fabric should at least meet a performance standard for Fire Resistant (FR) fabrics. – why re-invent the wheel?

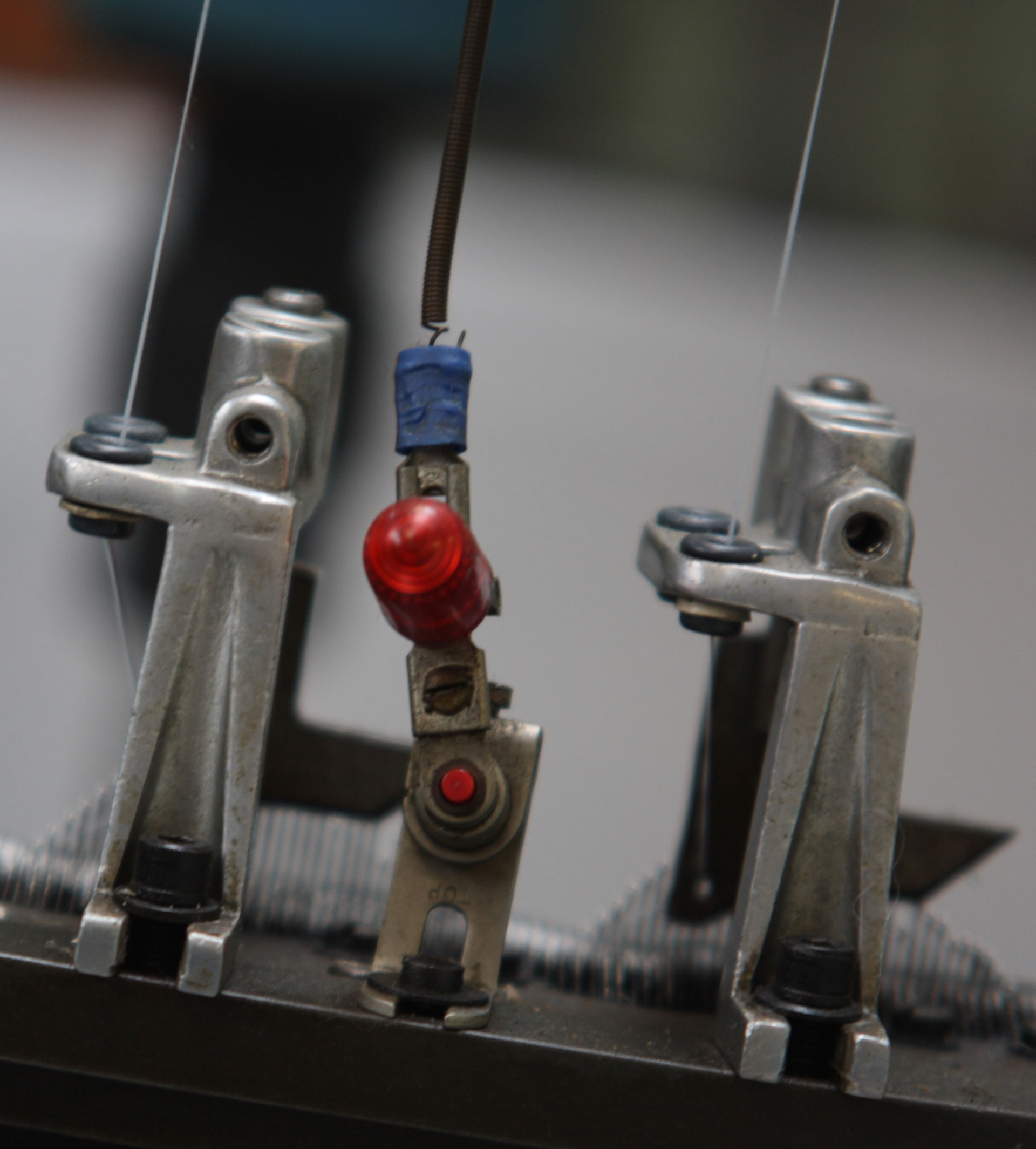

Shock/explosion resistance

The fabric should offer protection against explosion, flying debris or shrapnel. Fabric selection should consider fabric density, potential impact conditions, projectile mass, projectile geometry, and striking velocity.

Abrasion resistance

This ability helps to keep the material’s original structure and look, extending the life of a product. The blanket should be suitable for multi fire use up to at least 5 fires, and small rips/tears should be easily (and cost effectively) repaired (using a repair kit), to prolong the life of the product and secure value for money.

Non-conductive, and water/weather resistant

A blanket could be left outside in all weathers, and after use it should be easily cleaned and decontaminated. It should also be possible to repair the blanket to support multiple use and value for money.

Design Standards of the FireShell Textile Material

These standards are not an exhaustive list, but they illustrate the thinking, rationale and quality that underpins our approach to delivering/procuring a high-performance, high-quality product, that will protect first responders, and minimise fire spread/fire damage.